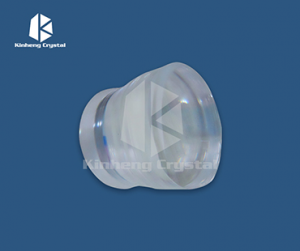

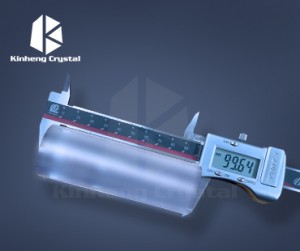

MgF2 Substrate

Description

MgF2 is used as a lens, prism and window for wavelength from 110nm to 7.5μm. It is a most suitable material as window for ArF Excimer Laser, for the reason of its good transmission at 193nm. It is also effective as an optical polarizing in the ultraviolet region.

Properties

|

Density(g/cm3) |

3.18 |

|

Melting Point(℃) |

1255 |

|

Thermal Conductivity |

0.3 Wm-1K-1 at 300K |

|

Thermal Expansion |

13.7 x 10-6 /℃ parallel c-axis 8.9 x 10-6 /℃ perpendicular c-axis |

|

Knoop Hardness |

415 with 100g indenter (kg/mm2) |

|

Specific Heat Capacity |

1003 J/(kg.k) |

|

Dielectric Constant |

1.87 at 1MHz parallel c-axis 1.45 at 1MHz perpendicular c-axis |

|

Youngs Modulus (E) |

138.5 GPa |

|

Shear Modulus (G) |

54.66 GPa |

|

Bulk Modulus (K) |

101.32 GPa |

|

Elastic Coefficient |

C11=164; C12=53; C44=33.7 C13=63; C66=96 |

|

Apparent Elastic Limit |

49.6 MPa (7200 psi) |

|

Poisson Ratio |

0.276 |

MgF2 Substrate Definition

MgF2 substrate refers to a substrate made of magnesium fluoride (MgF2) crystal material. MgF2 is an inorganic compound composed of magnesium (Mg) and fluorine (F) elements.

MgF2 substrates have several notable properties that make them popular in a variety of applications, especially in the fields of optics and thin film deposition:

1. High transparency: MgF2 has excellent transparency in the ultraviolet (UV), visible and infrared (IR) regions of the electromagnetic spectrum. It has a broad transmission range from ultraviolet at about 115 nm to infrared at about 7,500 nm.

2. Low index of refraction: MgF2 has a relatively low index of refraction, which makes it an ideal material for AR coatings and optics, as it minimizes unwanted reflections and improves light transmission.

3. Low absorption: MgF2 exhibits low absorption in the ultraviolet and visible spectral regions. This property makes it useful in applications requiring high optical clarity, such as lenses, prisms, and windows for ultraviolet or visible beams.

4. Chemical stability: MgF2 is chemically stable, resistant to a wide range of chemicals, and maintains its optical and physical properties under a wide range of environmental conditions.

5. Thermal stability: MgF2 has a high melting point and can withstand high working temperatures without significant degradation.

MgF2 substrates are commonly used in optical coatings, thin film deposition processes, and optical windows or lenses in various devices and systems. They can also serve as buffer layers or templates for the growth of other thin films, such as semiconductor materials or metallic coatings.

These substrates are typically produced using techniques such as vapor deposition or physical vapor transport methods, where MgF2 material is deposited on a suitable substrate material or grown as a single crystal. Depending on application requirements, substrates can be in the form of wafers, plates, or custom shapes.