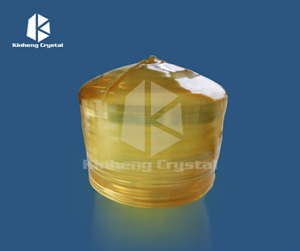

NaI(Tl) Scintillator, NaI(Tl) Crystal, NaI(Tl) Scintillation Crystal

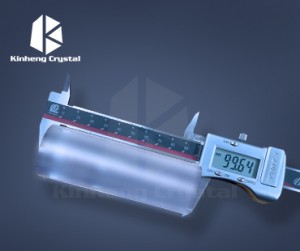

Shape and Typical Size

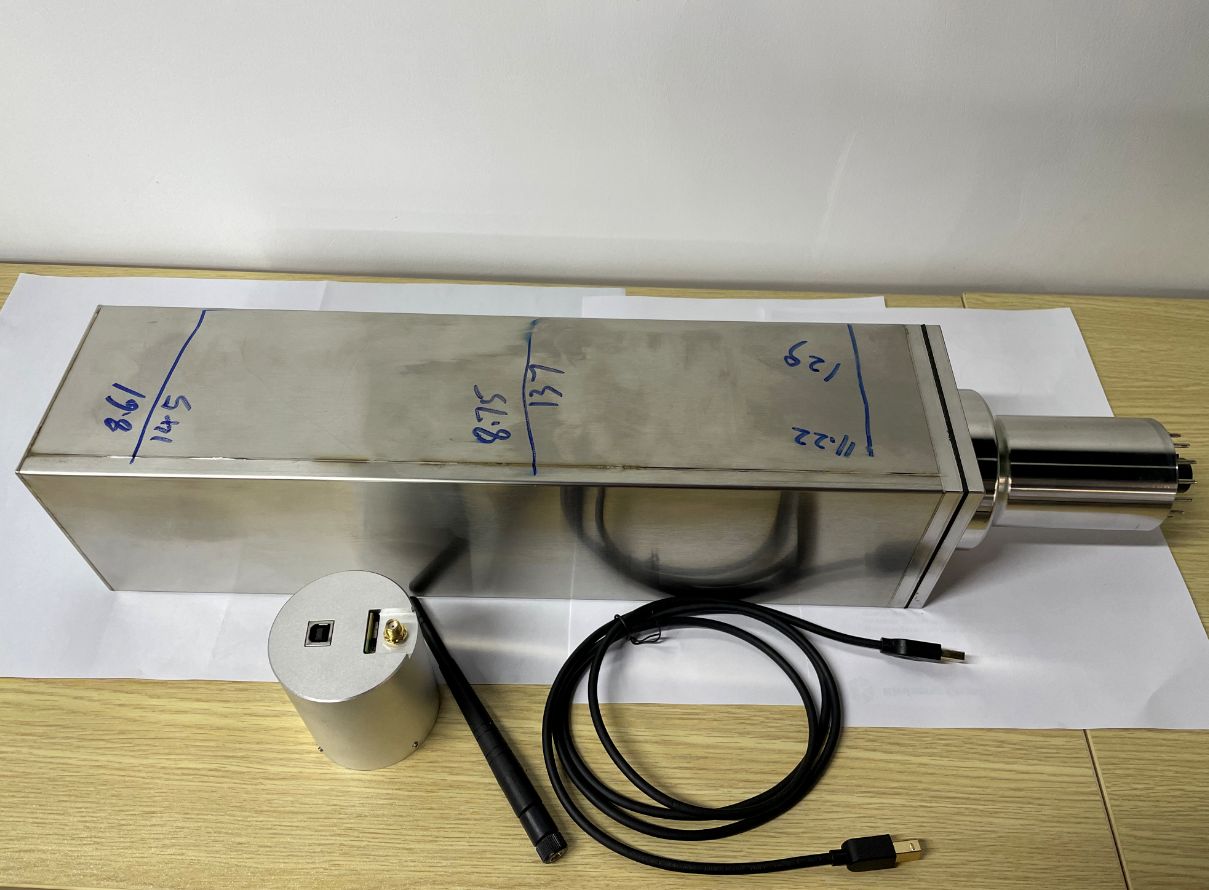

End-well, cubic Shape, side open well, cylinder. Dia1”x1”, Dia2” x2, Dia3”x3”, Dia5”x5”, 2”x4”x16”, 4”x4”x16”, Anti-Compton detector.

Available in single crystal, polycrystalline or forged crystals for oil logging industry.

Advantage

● Cost effective

● Larger size available

● High light output/ detection efficiency

● Single /polycrystal/forged crystal available

● Wavelength well matched PMT read out

● NaI(Tl) forged crystal for oil logging

● MWD/LWD

Application

● Nuclear medicine

● Environmental measurements

● Geophysics

● High-energy physics

● Radiation detection

Properties

| Density(g/cm3) |

3.67 |

| Melting Point (K) |

924 |

| Thermal Expansion Coefficient (K-1) |

47.4 x 10-6 |

| Hardness (Mho) |

2 |

| Hygroscopic |

Yes |

| Wavelength of Emission Maximum (nm) |

420 |

| Refractive Index at Emission Maximum |

1.85 |

| Primary Decay Time(ns) |

250 |

| Temperature Coefficient of Light Yield |

0.3% K-¹ |

| Light Yield (photons/keV) |

38 |

Product Description

NaI(Tl) stands for sodium iodide doped with thallium. It is a scintillation material used to detect radiation, especially gamma rays. When gamma rays hit the NaI(Tl) crystal, it causes the Tl atoms to emit a flash of light, which is detected by the photocathode and converted into an electrical signal. NaI(Tl) is commonly used in gamma spectroscopy, medical imaging, and environmental monitoring.

A polycrystalline scintillator is a scintillator composed of multiple small crystal grains instead of a single large crystal like a single crystal scintillator. These small particles are often grown together through a process called solid-state sintering, in which individual particles are brought into contact with each other and heated to high temperatures until they fuse together. This is different from the single crystal growth process used for single crystal scintillators. Polycrystalline scintillators have several advantages over single crystal scintillators, such as lower production costs and improved mechanical and thermal stability. However, they may have lower energy resolution and lower light output compared to single crystal scintillators.

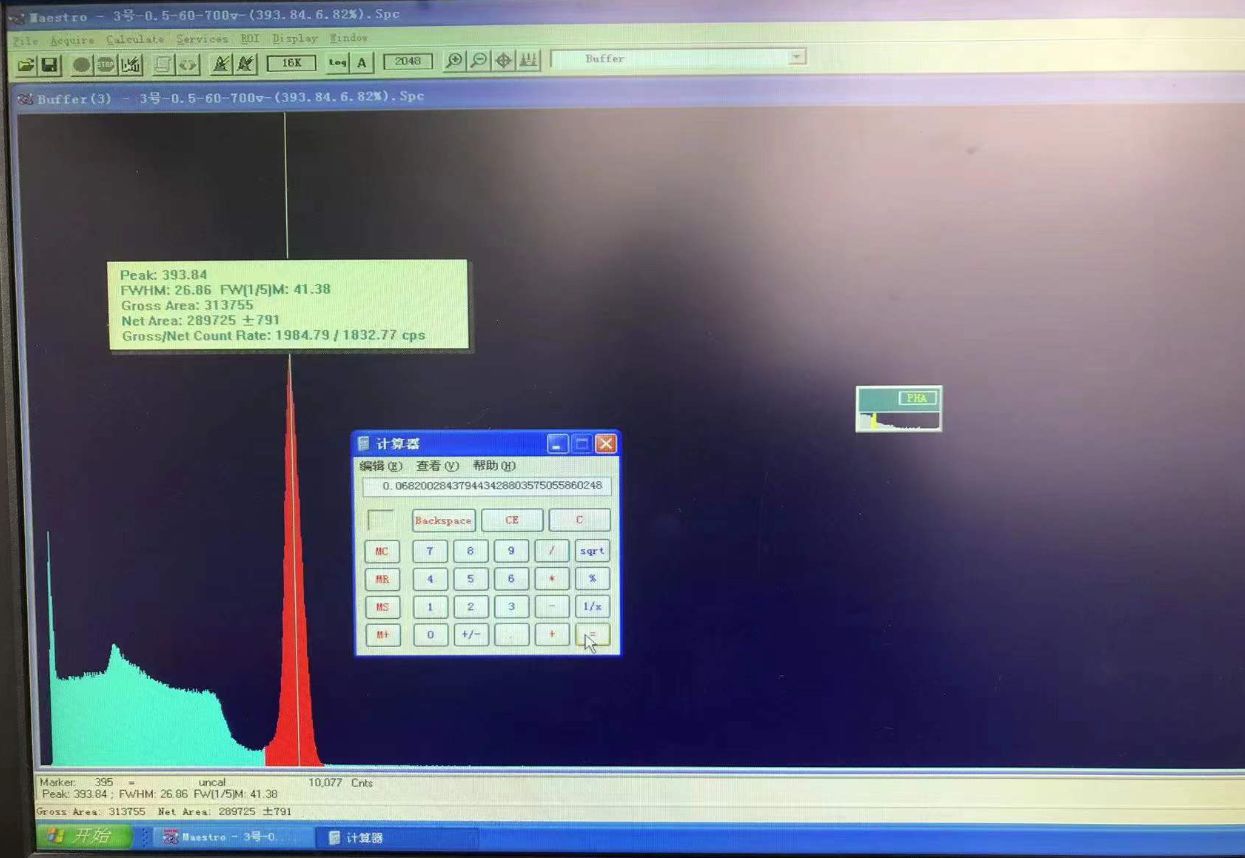

Energy Resolution

6.8%, Cs137 @ 662Kev

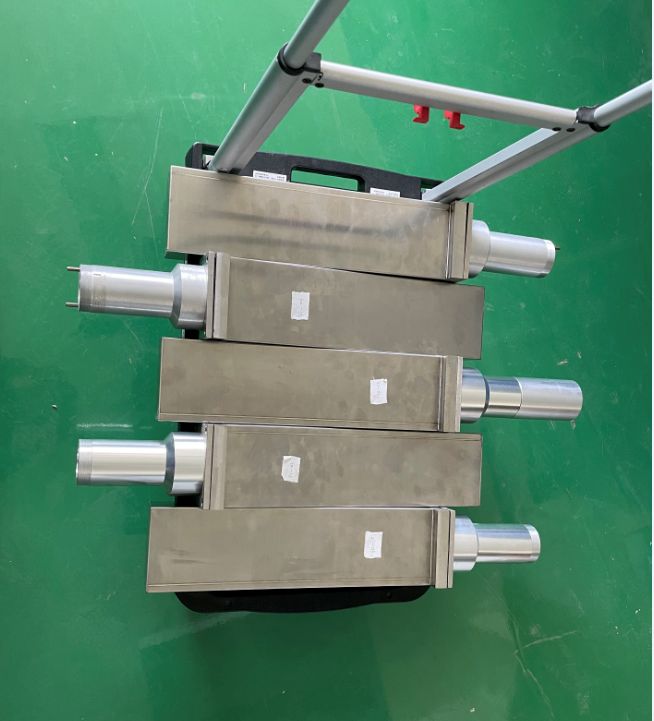

Forged scintillator for High temperature 175 degree, Logging industry

High temperature+ Welding encapsulation.

2L

4L

SDdetector

FAQ

NaI(Tl) scintillator has been widely used in the petroleum logging industry due to its excellent performance and functions. Made from sodium iodide crystals doped with thallium, these scintillators are used to detect and measure gamma radiation in a variety of applications, including oil well logging.

In the petroleum logging industry, NaI(Tl) scintillator plays a vital role in the exploration and production of petroleum reserves. When a NaI(Tl) crystal is exposed to gamma radiation emitted by the formation surrounding an oil well, it absorbs the energy and re-emits it in the form of pulses of visible light. These light pulses are then converted into electrical signals, which can be analyzed to determine the composition and density of the surrounding rock formations. This information is critical for assessing a well's potential productivity and optimizing the recovery process.

One of the main advantages of NaI(Tl) scintillators in petroleum logging is their high sensitivity to gamma radiation. This allows them to accurately detect and measure low-level radiation, providing valuable insights into the geological characteristics of underground formations. Additionally, NaI(Tl) scintillators have excellent energy resolution, enabling precise identification of different gamma ray energies associated with specific elements present in rock formations.

Additionally, NaI(Tl) scintillators are known for their durability and stability, making them ideally suited for the harsh and demanding conditions encountered in petroleum logging operations. Their rugged nature allows them to withstand high temperatures, pressures and exposure to a wide range of chemicals commonly found in oil wells.

In summary, the use of NaI(Tl) scintillator in the petroleum logging industry has significantly improved the efficiency and accuracy of geological survey and logging activities. Their ability to provide detailed information about subsurface formations has been proven to help optimize oil recovery processes and maximize well productivity. As technology continues to advance, NaI(Tl) scintillator is expected to remain an indispensable tool in the oil and gas industry, contributing to the continued advancement of exploration and production technology.